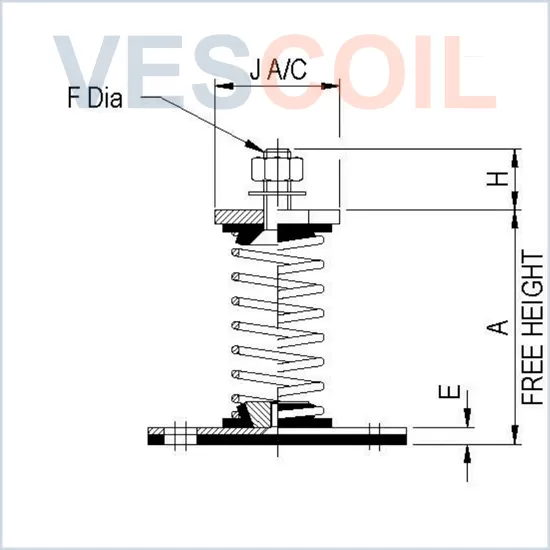

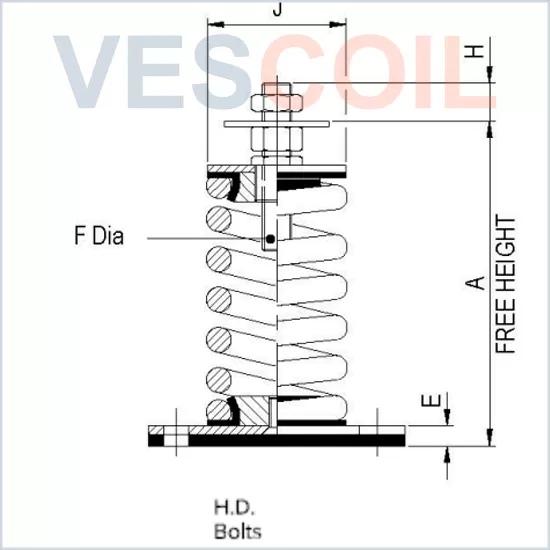

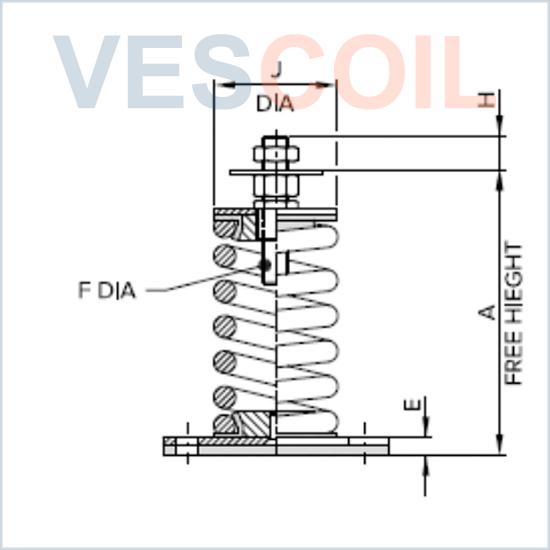

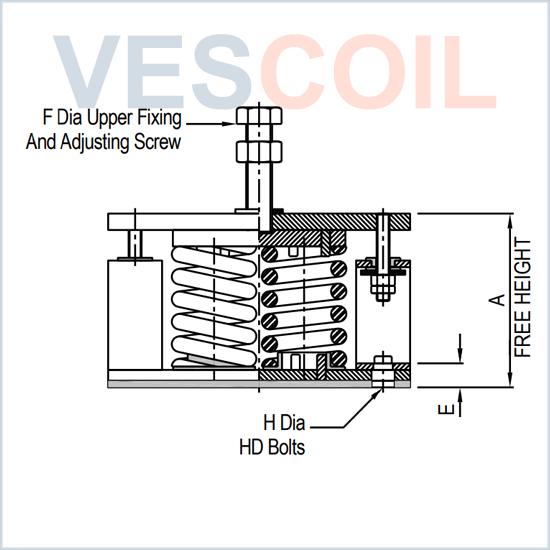

OPEN SPRING MOUNTING – TYPE OSB, OSS & OS25 – DEFLECTION 20 / 29 MM – LOAD 10 / 2300 KG

This unique range of Open Spring mountings uses integral rubber end fixing of the springs which sets them apart from all other designs. Larger capacity open spring mountings use rubber grommets and base pads to ensure no direct metal path between the machine and the seating, thus enhancing high frequency noise isolation.

Originally designed for use with Type IPF Inertia Pouring Frames, the OS mountings are now widely used to isolate vibration from every conceivable type of rotating and reciprocating machine. Where control of transient motion is required Open Spring mountings can be used in conjunction with our Viscous Dampers Type SFD.

Fig:

9412

Class & Approvals:

LR / UKAS

Rated load (kg):

10 – 2300 kg

Bolt dia:

M8 – M24

Deflection at rated load:

20 – 29 mm

HD Bolts:

M6 – M16

Machine speeds:

300 up to 2000 rpm

Efficiency %:

15 mm defl 68,7 – 98,5 / 25 mm defl 34,0 – 99,1

Markets:

Maritime / Offshore / Industry / Energy / Petrochemical

Frame:

All steel components are Zinc plated

Application:

Axial and Centrifugal Fans / Air Handling Units /

Pipework / Pumps / Generating sets / Compressors

No rights can be derived from the information on this website and our documents. Information can be manufacture dependent.